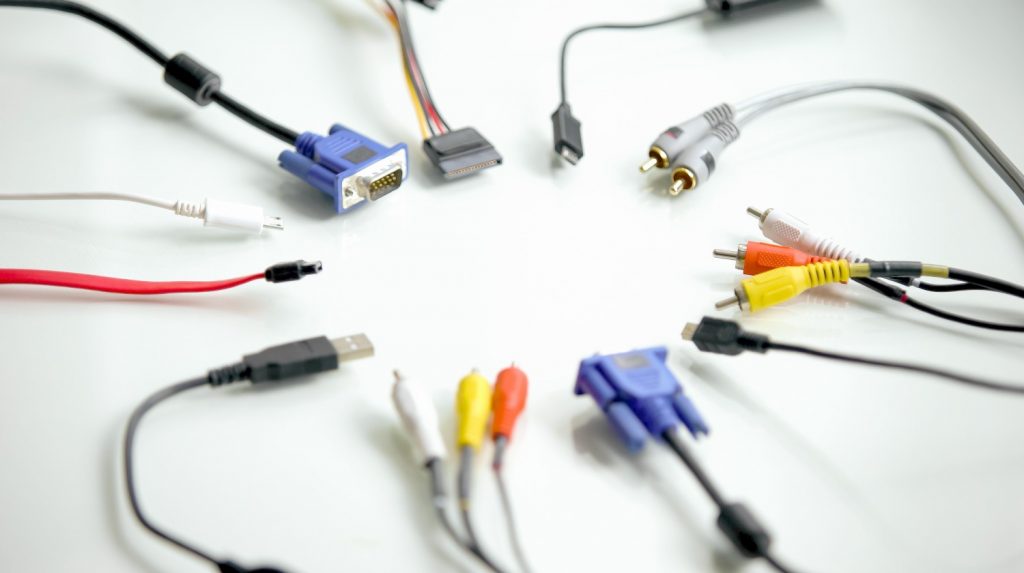

While Electronic Circuits can process signals and turn out outputs, they nearly always have to be connected to external elements, power sources, inputs, and outputs. These connect through the utilization of connectors, and they are available in many varieties, shapes, sizes, and ratings.

Selecting the incorrect connector as per your usage will cause various problems, from large product sizes to elements catching fire. Therefore, understanding connectors is imperative. This article is mainly about brass terminal connectors. With no waste of time, let’s gets complete information about connectors and their types.

What are connectors?

A circuit consists of a large number of elements, together with wires and cables. Connectors are a must part of these to create an eternal path for current to flow. Connectors have male-ends (plugs), and female-ends (jacks) hook up, forming either a permanent affiliation or, more often, a short-lived affiliation that can be assembled and removed with special tools.

Connectors drastically cut back the time, effort, and personnel required to produce, collect, and put in electrical devices, their elements further as wirings.

Composition of connector

Most brass terminal connectors have two main components – the housing and terminals for creating a connector.

● Housing

The housing is that structure or case which contains the terminals, ensures the stability of connections, and shields the electrical contacts from short-circuiting and environmental hazards. Connector housings are plastic products; however, some also use different insulating materials like ceramics.

● Terminals

Terminals are the pins during a connector that gives conductivity to form the affiliation securely. These are nearly always composed of metal. However, a number of them use different conducting materials (carbon, silicon, etc.).

Features and properties of connectors

For some applications, brass terminal connectors that possess different options could be needed and most well-liked :

● Keyed connectors

These are for attaching if they’re within the correct orientation. Brass terminal connectors prevent accidental harm to the pins and prevent users from inserting them within the wrong circuit.

● Locked connectors

A lockup mechanism ensures the connectors are held in place, preventing connections from breaking accidentally or shifting when the connector is bumped or jolted.

● Hermetically sealed connectors

Some applications need an electrical affiliation that can submerge in water. These connectors are purpose-built to be functioning below water and face up to pressure upto sure depths.

● Water-resistance connectors

While they typically cannot face up to being submerged, these connectors offer protection for the electrical connections against water damages from splashes or occasional wetness.

● Moisture/ oil resistant connectors

These are to guard the electric circuit against harm caused by oil and wet.

● EMI or RFI filtering

Additional options built into the housing to prime shield the connectors from electromagnetic interference (EMF) or radio interference (RFI), affecting circuits carrying electrical signals.

● ESD secure connectors

The electrostatic discharge will harm wiring and elements. ESD secure connectors offer further protection against this.

Specifications

Choosing the suitable brass terminal connector that can work and minimize risks should consider some factors, such as the application, style of connectors, and the strength of the electrical current the circuit can carry. These can be countermine into two classifications:

● Performance parameter

Performance parameters got to be hand-picked supported the conditions during which the electric circuit is to operate:

- Current – This rating describes the speed of electricity flow (current) a connector has to accommodate. Current has a unit, amperes (A or amps). This rating on a connector can sometimes be within 1A to 50A, although smaller and bigger ones are on the market for special

- Voltage – The voltage rating describes the vary and kind of voltage meant to The unit is volts for the voltage and AC and DC. Typically, the ratings will be 50V, 125V, 250V, and 600V; however, others are available too.

- The operational temperature describes the varied, counseled temperature and maximum/ minimum safe operating temperature for the electrical

Physical parameters

Physical parameters ought to be hand-picked rigorously since they describe the electrical connecter however is meant, the connections it will be used for and far a lot of:

- Contact pitch is often the gap between the centers of adjacent pins or the terminals during a It holds millimeters as a unit. Larger contact pitches mean fewer connections or pins per space, which reduces electrical arcing and, thereby, interference. However, it will increase the general size of the connectors.

- Several contacts – aside from the contact patch, the number of contacts or individual semiconductive components in electrical connectors can

- Material – whereas the connector casings are sometimes a product of plastic, the materials used for the connector are a mix of metal and plastic for insulation. Brass terminal connectors have metal content which might vary from zinc 5-40%, most minor expensive metal to get by weight; elastic; strong; high electrical phenomenon, employed in KK

Type of connectors

- Board-to-board connectors

These want to connect PCBs while not using a cable. They save area on cables, creating them appropriate for systems with restricted areas. The PCBs may connect to mistreatment connectors in parallel or perpendicular configurations. A connector that connects 2 PCBs during a stacking configuration is a mezzanine connector. However, the term is typically to describe perpendicular or side-by-side PCB arrangements.

These arrangements are sometimes seen on the motherboard-daughterboard arrangements, wherever the main focus is on the parallel arrangement.

- Wire cable connectors

wire-to-wire connectors connect two wires, as the name suggests. One end of the connector connects to the wire. The opposite finish of the connector forms a divisible interface. The permanent will create mistreatment of either crimping or insulation displacement contacts.

- Wire/cable to board connectors

The wire connections are similar to the ones used for wire-to-wire connection, and the board connections are, for the most part – press-in or soldered two-piece connectors, although some card versions remain in use.

The mating interface for the detachable connection may be identical to that of a wire-to-wire connector from the same product family. While there are many applications of wire-to-board connectors, the trend is towards cable-to-board connectors, or cable assemblies, to take advantage of the benefits of IDC.

Conclusion

Brass terminal connectors are available in several designs and choosing the right one is very important. Learning to recognize the different types of connectors and their advantages and disadvantages can save electrician’s time and money by understanding their product, what it will experience, and what environment it will find helpful.