It’s always critical to use latest methods and technologies in the automobile, construction, defense, and other available manufacturing industries. While manufacturing units focus on production of quality and lightweight molded gratings, customers make requests for fiberglass molded gratings as these products carry various advantages and features. It’s like using multi-feature yet durable product when they use FRP gratings.

Composites Are The Real Hero In The Industry

Technically, FRP materials are the composites that use different materials like concrete, cement, etc. Thus, these are ideally used for construction of bridges, buildings, tanks, household fittings, and are used by automotive sector to produce complete structures of boat hulls and racing cars.

There are countless manufacturing companies available today that produce premium quality products with excellent service before and after sales, and increasing client list.

Some of the main equipments required by these companies are pultrusion dies, rod mould, sink mould, platform mould, beam mould, FRP window frame, FRP ladder mould, etc.

FRP Products Possess High Tensile Strength

Another crucial thing supplied by manufacturers is fiberglass pultrusion products and FRP items. When composite materials are produced with a continuous cross-section, it is known as pultrusion. The use of a quality pultrusion die is important in making pultrusions, and this technology needs to be made with precision, and can only be acquired with lots of experience.

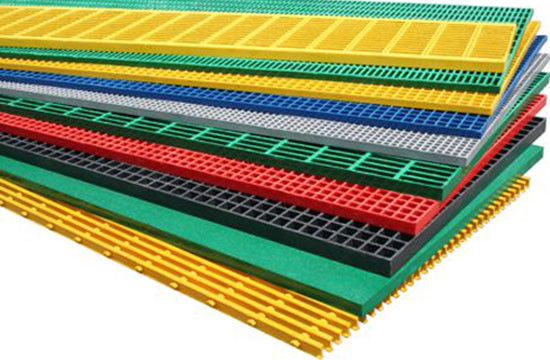

By using such technology, manufacturers are able to produce extremely versatile products that are rich in sturdiness and robustness. Moreover, FRP gratings are super light in weight and require minimal number of persons for installation.

Moreover, fiberglass molded gratings are made with super fine materials that do not corrode, crack, or break. And FRP gratings are least expensive in comparison with pultruded products. Being highly resistant to corrosion, many chemical and industrial plants owners prefer using FRP molded products inside their infrastructure. Thus, its high tensile strength and robustness make it perfect product for construction industry as a whole.

This article is published by experts who deal in GRP pultruded profiles and supply to automobile, defense, and other manufacturing industries. To know more about the company, you can visit its online website as well.