A skilled job that includes establishing strong bindings between metals by utilizing heat, pressure, and occasionally filler materials, welding is a trade that requires a lot of talent. To obtain expertise in welding, despite the fact that it is a very widespread skill, a significant amount of accuracy, knowledge, and practice are required.

Facts of the basic principles of welding is necessary in order to produce a connection that is both strong and trustworthy. It is not enough to just join two pieces of metal together; it is necessary to have this knowledge. Let us read further on details related what is spot welding and why it is important.

What Is Meant By The Term “Spot Welding”?

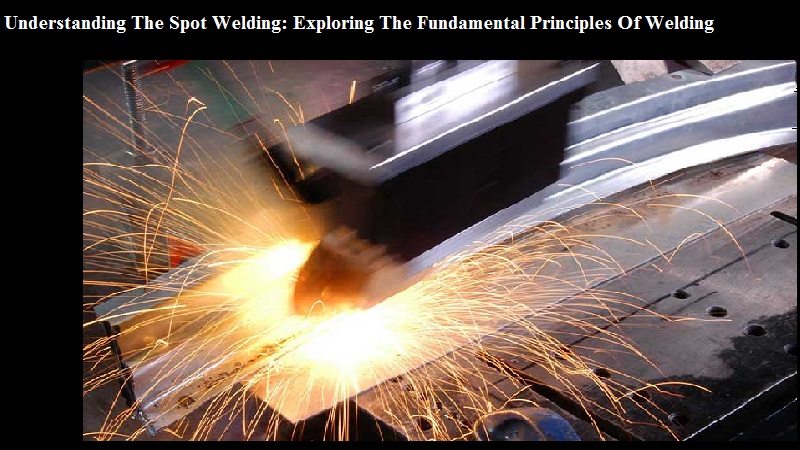

The method of spot welding, which is often referred to as resistance spot welding, is a kind of resistance welding. The application of pressure and heat from an electric current to the weld region is the primary function of this welding technique, which is mostly used for the purpose of connection of more than two sheets of metal together.

The electrodes made of copper alloy are brought into contact with the sheet surfaces, which results in the application of pressure and electric current. Additionally, heat is produced as a result of the passage of current through materials that are resistant to their current, such as low carbon steels.

Welding is not at all simple, despite the fact that the definition that was just presented could make it appear like it is. There are a few key concepts of welding that you should be familiar with:

- The ability to weld requires a high degree of competence as well as a practical understanding of several areas, including metallurgy, chemistry, and physics.

- Although welding is most often employed for joining metals, it may also be used for joining thermoplastic or wood components.

- This kind of junction is referred to as a weld joint or weldment.

- The substance that is utilized to assist produce this weld connection is known as the filler material, whereas the parent material consists of the pieces that are fused together.

- Through the use of heat welding, pressure welding, or both, welding is the process of joining together two materials of the same kind (for example, metal and metal or wood and wood).

- Welders add metal to the joint that is being welded in order to strengthen the joints. At the same time, a shielding gas such as carbon dioxide shields the joint from contamination caused by natural elements.

- The chemical, mechanical, and physical properties of various metals determine the characteristics of their reactions, which might vary from metal to metal.

- Heat has the power to produce changes in the ductility, malleability, and strength of metal. By applying sufficient heat, welding may be used to straighten out a piece of metal that has been deformed.

- The metal is heated and cooled throughout the welding process; there is no other chemical reaction that takes place during this particular process. On the other hand, if oxygen interacts with the molten metal, the weld will become very weak. Through the use of protective gases in the vicinity of the weld pool, oxygen and other impurities are prevented from causing damage to the joint.

- The crystalline structure of any metal may be altered and weakened by exposure to extreme heat.

What Are The Applications Of Spot Welding?

There are a variety of sectors that may benefit from spot welding, such as the automobile industry, the aerospace industry, the rail industry, white goods, metal furniture, electronics, medical development, and construction.

By taking the advantage of the simplicity with which spot welding can be automated when paired with robots and handling systems, it has become the most prevailing joining technique in large volume production lines. In particular, it has been the main joining process in the manufacture of steel automobiles for more than a century.

Setting Up And Getting Ready For Aspot Welding Job That Involves Spot Welding

Establishing and planning for a spot welding project is an important step that may have a significant impact on the quality of your welds as well as their overall success for the project. As a result, this phase is crucial. In order to ensure that you are fully prepared for the process of welding, it is essential to make certain that you have all of the tools and equipment that are necessary for the work. A spot welding machine, electrodes that are appropriate for the spot welding process, safety gear like as gloves and goggles, and any other materials that may be required for the specific operation.

Conclusion

The method of spot welding is an important one in many different sectors. One of the most significant and renowned manufacturers of such items, spot welding machines manufacturers adheres to the criteria that have been recognised by the industry.